FABRICATION

Fabrication is the process of translating computer-generated designs into physical objects using computer-controlled machinery. The methods I use include 3D printing, laser cutting, and CNC milling. By combining digital design tools with automated production, digital fabrication enables rapid prototyping, customization, and complex geometries that might be difficult or impossible to achieve through traditional manufacturing methods.

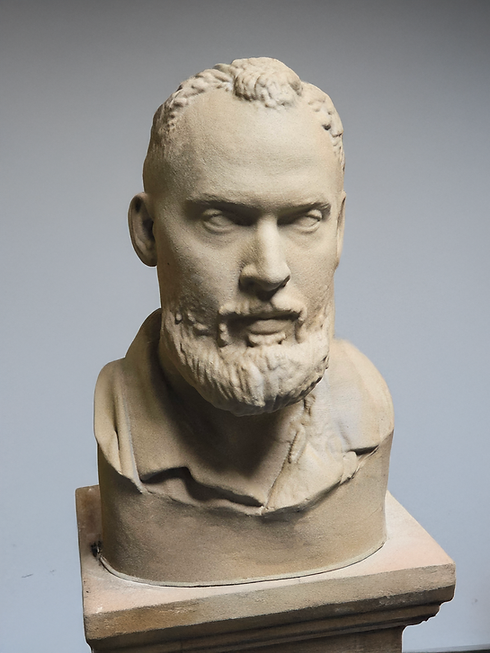

BUST

A bust preserves more than just a likeness, it captures presence, character, and legacy at a specific moment in time. Unlike photographs, which can fade or be lost in the endless stream of images. A bust provides a lasting, tangible representation that endures for generations.

Traditionally, creating such a piece required months of painstaking work by a sculptor. This bust, however, was completed in just two weeks, requiring only 15 hours across all stages of production—making a timeless art form both more accessible and more efficient without sacrificing impact.

ARTIST ROLE

3D Scanning

CAD Modeling

3D Printing

Cleanup and Sanding

Painting

RETROSPECTIVE

While the 3D scanner proved effective at capturing the detail of the face, it required the subject to remain still for 10 minutes while the scan was taken. Additionally the scanner could be a limitation if the subject is not in the local area. Splitting up the total 3d print into different sub-objects allowed me to print to scale, but I had to manually align each section during glue vs mechanical connections between sections.

PARRYING DAGGER

On a well-worn table of dark, weathered wood, an ancient parrying dagger rests upon a soft leather cloth, as if it has just been set down by a wandering adventurer. The dagger's blade, slender and sharp, glistens faintly in the dim light of a forgotten chamber, holding the echoes of a thousand battles fought in distant lands. Its cross guard, a twisted design hinting at both artistry and the warrior's skill.

ARTIST ROLE

Design Engineer

3D Printing

Cleanup and Painting

Product Visualization

RETROSPECTIVE

When creating this dagger, I carefully considered material stresses and paint type. Printing in ASA was the best choice for this project as it's durable and won't warp in direct sunlight. While it's not intended for actual combat, I optimized the print orientation to maximize durability within the design's limitations. This was the second knife handle I created with my 3d printer and the 'Textured Rustoleum' paint works amazingly well at adding grip.